DTF (Direct-To-Film) printing revolutionizes the printing industry by offering a highly cost-effective solution. Its efficiency streamlines processes, reduces waste, and cuts preparation time. Versatile, it enables custom product creation and optimizes printer operations. Future of printing is shaped by DTF's promise to minimize costs, reduce labor, and simplify production lines while maintaining consistent quality. Environmentally friendly, DTF aligns with sustainable practices, reducing harmful chemical use and appealing to eco-conscious consumers.

Discover how DTF (Direct to Fabric) printing is revolutionizing the industry as a cost-effective solution for businesses. This cutting-edge technology offers significant advantages over traditional methods, unlocking substantial savings while streamlining production processes. With its efficient and eco-friendly approach, DTF is not just a trend but the future of printing. Explore how it can transform your business by reducing costs, enhancing productivity, and promoting sustainability in this comprehensive guide.

- Unlocking Cost Savings: DTF's Advantage

- Efficient Production: Streamlining Processes

- Sustainable Future: Eco-Friendly Printing

Unlocking Cost Savings: DTF's Advantage

DTF (Direct-To-Film) printing offers a significant advantage when it comes to unlocking cost savings in the printing industry. One of the key benefits is its efficiency, as DTF allows for direct application of designs onto various surfaces, eliminating the need for intermediate steps like printing on paper or fabric first. This streamlined process reduces waste and minimizes the time required for preparation, making it a highly cost-effective solution.

Additionally, DTF’s versatility in creating custom sheets for heat pressing designs onto garments opens up endless possibilities for businesses. The cold peel dtf transfers ensure ease of application, while direct to film personalized hoodies showcase its ability to meet diverse customer demands. This level of customization not only enhances product offerings but also allows printers to optimize their operations, further reducing costs and increasing overall efficiency.

Efficient Production: Streamlining Processes

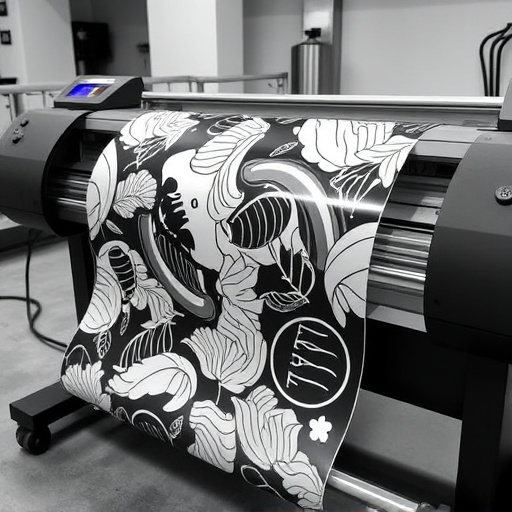

The future of printing lies in its ability to become increasingly cost-effective, and Direct to Fabric (DTF) technology is leading this revolution. One of the key advantages that makes DTF cost-effective is its efficient production process. By streamlining various steps traditionally involved in printing, DTF significantly reduces waste and time. In the context of DTF for apparel, this means minimizing setup times between prints, eliminating the need for intricate mechanical parts, and simplifying the overall production line.

This streamlined approach incorporates the use of DTF transfer film, which serves as a precise medium to convey design details directly onto the fabric. Unlike traditional heat press methods that can be labor-intensive and less accurate, DTF utilizes advanced printing technologies to ensure consistent quality across batches. As a result, apparel manufacturers can achieve higher productivity without compromising on product quality, ultimately contributing to its cost-effectiveness.

Sustainable Future: Eco-Friendly Printing

The printing industry is undergoing a significant transformation, and at the forefront of this revolution is the adoption of more sustainable practices. In light of growing environmental concerns, embracing eco-friendly methods is no longer an option but a necessity. DTF (Direct to Fabric) cost-effective printing stands out as a game-changer in this context. By utilizing dtf heat transfer paper, businesses can produce high-quality custom t-shirts and other garments with minimal waste. This innovative technique reduces the reliance on harmful chemicals often associated with traditional printing methods.

With a best DTF printer, the process becomes more efficient, allowing for precise and detailed designs while minimizing the environmental impact. The direct application of ink onto fabric through heat transfer ensures that only the necessary materials are used, reducing the waste typically generated by older printing technologies. This shift towards sustainability not only benefits the planet but also appeals to environmentally conscious consumers who increasingly demand eco-friendly products.

DTF (Direct To Forme) printing emerges as a game-changer in the printing industry, offering significant cost savings and efficiency. By streamlining production processes and embracing eco-friendly practices, DTF cost-effective methods are not just the future of printing but a sustainable one. Its advantages, from reduced waste to faster turnaround times, make it an attractive option for businesses seeking both quality and affordability. Adopting DTF technology is a strategic move towards a more efficient and environmentally conscious printing landscape.